hardness test short definition|principle of hardness tester : vendor Hardness definition. Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond). #telmasantosfamosinha #https://close.fans/telma #viralizanoreels #compartilharl #sejacriador #Comentários #calabreso. Telma Santos · Original audio

{plog:ftitle_list}

Resultado da Extranet - Adcos

Hardness definition. Hardness is the mechanical resistance of a material (specimen) to mechanical indentation by another harder body (indenter). The hardest natural material is the diamond, which is used for the indenter (industrial diamond).

The principle of electronically controlled and permanently monitored load application .What is Hardness – Definition. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. .

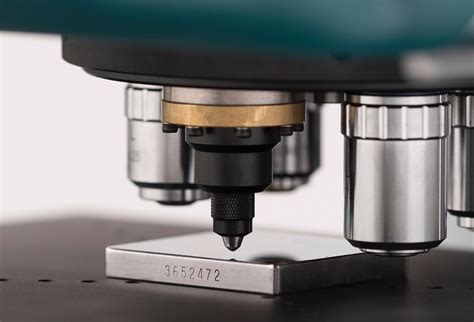

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well .

In-depth definition of hardness testing involves evaluating the hardness level of a material by measuring the depth or area of indentation left by an indenter of a specific shape, applied with . A hardness test is a method employed to measure the hardness of a material. Hardness refers to a material’s resistance to permanent indentation. There are numerous . Hardness testing is a quantitative test method. In metallurgical science, the hardness value of a material is directly related to the type of microstructure. Ferrite is softer while martensitic is a hard microstructure.

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. Hardness testing is a mechanical test that measures a material’s resistance to indentation, scratching, or abrasion. The test is performed by applying a specific force on the surface of the material using a .Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the .

The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the test indentation is very small in a Vickers microhardness test, it is .Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. The Mohs hardness of a mineral is determined by observing whether its surface is scratched by a substance of known or . the test may only loosen grains without .An entry-level Rockwell automatic hardness tester for high accuracy and a short cycle time. Duramin 160. . The definition of hardness testing is ‘a test to determine the resistance a material exhibits to permanent deformation by penetration of another harder material.’ However, hardness is not a fundamental property of a material.Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

Common indentation hardness scales are Brinell, Rockwell and Vickers. See also: Hardness. Knoop Hardness Test. The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop and . The hardness test is a way to assess the quality of a material, determine its properties, and evaluate its suitability for a specific application. What is Hardness Testing? Hardness testing is a mechanical test that measures a material’s resistance to indentation, scratching, or abrasion. The test is performed by applying a specific force on .

why is hardness testing important

Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy.The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels.The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is . The Shore A hardness scale is widely used in the polymer and plastics industry to characterize the hardness of various materials. Manufacturers use durometer testing as a quality check for manufactured products. For example, silicone hardness or rubber hardness can easily be measured and evaluated against manufacturing standards. German mineralogist Mohs first devised the Mohs hardness test to measure the scratch hardness of materials. In this test, the material is scratched with a reference material that has a defined hardness. A numerical hardness value is assigned to the test material based on the results of the test. Mohs hardness test uses 10 reference materials of .

iphone 6 otterbox drop test

Hardness refers to the ability of a material to resist deformation, scratching, or penetration. It is a key physical property that indicates how well a substance can withstand mechanical forces and is often measured by various scales such as Mohs hardness scale or the Vickers hardness test. This property can also provide insights into a material's composition, structure, and its potential .Hardness Definition. Hardness is a metric that measures how resistant a material is to localised plastic deformation caused by mechanical indentation or abrasion. It has important diagnostic properties in mineral identification or abrasion. . Although the mohs hardness test is useful for identifying minerals in the environment, it is not .

hardness assurance within a project. Section 7 discusses emerging radiation hardness assurance issues. 2.0 RADIATION HARDNESS ASSURANCE OVERVIEW Figure 1 gives an overview of the radiation hardness assurance process. A short description of the different steps follows with details given in the subsequent chapters. This process is iterative.

iphone 6 otterbox resurgence drop test

types of hardness testing methods

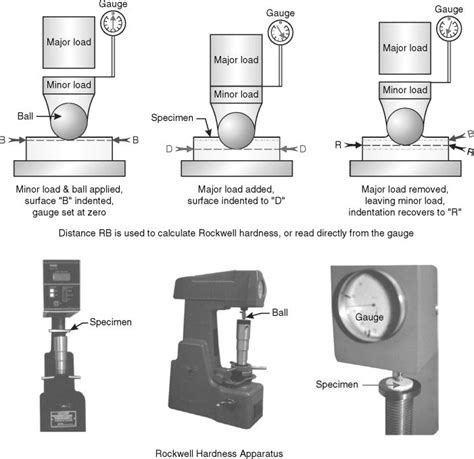

Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)heat treatment process and the working temperature. Mostly, the strength, toughness and hardness of materials are to be measured after the metal forming process [2]. The main objective of the paper is to . Definition, Testing and Application International Journal of Modern Studies in Mechanical Engineering (IJMSME) Page | 31 Figure2. .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .

What is Brinell Hardness Test? In Brinell Hardness Test, an indenter, a ball made of carbide metal (formerly hardened steel) with diameter D, is pressed in the test object surface and the diameter ‘d’ of the indentation is .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Rockwell hardness definition: 0.002mm residual indentation depth is a Rockwell hardness unit. K – constant, 130 for steel ball indenter and 100 for diamond indenter. Table 3-6 Test Specification and .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds. This type of hardness is typically measured on a scale known as the Rockwell Scale. Figure 1. Rockwell hardness testing equipment. (Source: Sorapol Ujjin / Dreamstime.com) Scratch Hardness. Scratch hardness, as its name implies, is a material’s ability to resist scratches and abrasion on its surface.

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly.

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

Tablet hardness testing is a laboratory technique used by the pharmaceutical industry to determine the breaking point and structural integrity of a tablet and find out how it changes "under conditions of storage, transportation, packaging and handling before usage" [1] The breaking point of a tablet is based on its shape. [2] It is similar to friability testing, [1] but they are not the . This definition explains the meaning of Vickers Hardness Test and why it matters. #.. Mitigating Corrosion Under Insulation and Supporting the Longevity of Industrial Pipe Insulating Systems . The Vickers hardness test is a test performed to measure the hardness of materials, specifically thin sections and small parts. It is comprised of a . The resilience of rubbers and plastics means that the indentation reading may change over time, so the indentation time is sometimes reported alongside the hardness number. The results obtained from a Shore Durometer hardness test are a useful measure of the relative resistance to indentation of various grades of polymers.An entry-level Rockwell automatic hardness tester for high accuracy and a short cycle time. . DEFINITION OF THE VICKERS HARDNESS TEST The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials. .

principle of hardness tester

WEB20 de out. de 2021 · Get Tech N9ne - Face Off (Lyrics) Joey Cool, King Iso & Dwayne Johnson | it's about drive it's about power: https://spoti.fi/2nMhW6J ⭐Follow TikTokTunesInsta.

hardness test short definition|principle of hardness tester